Bore well Compressor

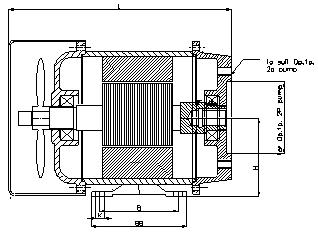

Double Flange Motors

Mono block Pumps

Features

- Light Weight

- Noise less Function

- Less Power Consumption

- Graded Raw Materials

- Thermal overload Protector

- Stainless Steel Shafts

- High Performance

- Compact Design

- Maintenance Free

Applications

- Industrial & Residential Use

- High Rise Building

- Water Circulating Systems

- Lawn and garden Watering

|

Pump ModelNO |

Pipe Size in mm |

Motor |

Total Head in Meters |

|||||||

|

Discharge in LPM |

||||||||||

|

Sue |

Del |

HP |

KW |

10 |

14 |

16 |

20 |

24 |

28 |

|

|

SWP 1 |

25 |

25 |

0.5 |

0.37 |

1.60 |

1.40 |

0.40 |

– |

– |

– |

|

SWP 2 |

33 |

25 |

1.0 |

0.75 |

– |

2.24 |

2.05 |

1.60 |

1.20 |

0.24 |

|

SWP 3 |

40 |

40 |

1.0 |

0.75 |

3.36 |

3.30 |

2.60 |

– |

– |

– |

|

SWP 4 |

40 |

40 |

1.5 |

1.1 |

4.78 |

4.60 |

3.60 |

3.00 |

– |

– |

|

SWP 5 |

40 |

40 |

1.5 |

1.1 |

– |

3.00 |

2.80 |

2.16 |

1.70 |

0.80 |

Selection Chart

|

K.W |

H.P |

2 Pole |

4 Pole |

6 Pole |

8 Pole |

|

0.09 |

0.125 |

56 |

56 |

71 |

71 |

|

0.12 |

0.16 |

56 |

63 |

71 |

71 |

|

0.18 |

0.25 |

63 |

63 |

71 |

80 |

|

0.25 |

0.33 |

63 |

71 |

71 |

80 |

|

0.37 |

0.5 |

71 |

71 |

80 |

90S |

|

0.55 |

0.75 |

71 |

80 |

80 |

90L |

|

0.75 |

1.0 |

80 |

80 |

90S |

100L |

|

1.1 |

1.5 |

80 |

90S |

90L |

100L |

|

1.5 |

2.0 |

90S |

90L |

100L |

112 M |

|

K.W |

H.P |

2 Pole |

4 Pole |

6 Pole |

8 Pole |

|

2.2 |

3.0 |

90L |

100L |

112M |

130S |

|

3.7 |

5.0 |

100L |

112S |

132M |

160M |

|

5.5 |

7.5 |

132S |

132S |

132M |

160M |

|

7.5 |

10.0 |

132S |

132M |

160M |

160L |

|

9.3 |

12.5 |

132M |

160M |

160L |

180M |

|

11.0 |

15.0 |

160M |

160M |

160L |

180L |

|

15.0 |

20.0 |

160M |

160L |

180L |

200L |

|

18.5 |

25.0 |

160L |

180M |

200L |

225S |

Self Priming Pumps

Features

- High Discharge

- Light Weight

- Aluminium Extrusion Body

- Capacitors start & run design

- Stainless Steel Shaft

- Brass Forged Impeller

- Maintenance free ceramic mechanical seal

- Contain High quality raw materials

- Consumes less Power

Applications

- Domestic water pumping to overhead tanks

- Foundations

- Gardening

- Water curing at construction sites

Performance Chart

|

Pump Size |

Kw / HP |

Speed RPM |

T.Head |

|

|||||||||||||||||||||||||||

|

18 x 18 |

0.18 / 0.25 |

2840 |

18 |

1500 |

1000 |

400 |

– |

– |

– |

– |

|||||||||||||||||||||

|

25 x 25 |

0.37 / 0.5 |

2840 |

30 |

2200 |

1800 |

1500 |

1200 |

1100` |

850 |

|

|||||||||||||||||||||

|

25×25 |

0.75 / 1.0 |

2840 |

36 |

3300 |

3000 |

2600 |

2200 |

2200 |

1900 |

1500 |

|||||||||||||||||||||

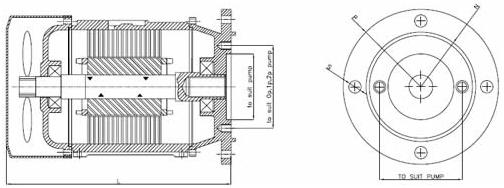

Hollow Shaft Motors

Design features

Energy efficient (EFF1 and EFF2) motor and optimal fits based on the pump dimensions provides trouble free operations. This model comes with bigger series of bearings on the drive end and non drive end when compared to the standard motors

Alignment

Concentricity between pump and motor is within 20microns

- RANGE: 0.25HP TO 30 HP

- VOLTAGE:220V/415V/670v/48V/42V

- SPEED: 2880/1440/960

- Class of insulation: F

- Mounting: foot, flange as per IS2223 and IS 1231 and custom built on request

- Degree of protection: IP55 standard

- PUMPS: Stark Motors Hollow Shaft Motors Are Designed Generally to Suit all brands of hydraulic pumps

Hollow shaft flange mounted motors

|

Frame |

HP |

Flange |

P |

M |

N |

S |

L |

|

71 |

0.5 HP |

F130B |

160 |

130 |

110 J6 |

10 |

200 |

|

80 |

1.0 HP |

F165B |

200 |

165 |

130 J6 |

12 |

230 |

|

90S |

1.5 HP |

F165B |

200 |

165 |

130 J6 |

12 |

240 |

|

90L |

2.0 HP |

F165B |

200 |

165 |

130 J6 |

12 |

265 |

|

100 |

3.0 HP |

F215 B |

250 |

215 |

180J6 |

15 |

300 |

|

112M |

5.0 HP |

F215 B |

250 |

215 |

180J6 |

15 |

325 |

|

132S |

7.5HP |

F265 B |

300 |

265 |

250J6 |

15 |

358 |

|

132M |

10.0 HP |

F265B |

300 |

265 |

250J6 |

15 |

398 |

|

160M |

15hp |

F300 B |

350 |

300 |

250J6 |

19 |

622 |

|

160L |

20 HP |

F300B |

350 |

300 |

250J6 |

19 |

622 |

Hollow shaft foot mounted motors

|

Frame |

HP |

A |

B |

H |

K |

L |

|

71 |

0.5 HP |

112 |

90 |

71 |

7 |

235 |

|

80 |

1.0 HP |

125 |

100 |

80 |

10 |

270 |

|

90S |

1.5 HP |

140 |

100 |

90 |

10 |

290 |

|

90L |

2.0 HP |

140 |

125 |

90 |

10 |

315 |

|

100 |

3.0 HP |

160 |

140 |

100 |

12 |

360 |

|

112M |

5.0 HP |

190 |

140 |

112 |

12 |

385 |

|

132S |

7.5HP |

216 |

140 |

132 |

12 |

438 |

|

132M |

10.HP |

216 |

178 |

132 |

12 |

478 |

|

160M |

15Hp |

254 |

210 |

160 |

15 |

580 |

|

160L |

20 HP |

254 |

254 |

160 |

15 |

622 |

|

180 L |

30HP |

279 |

279 |

180 |

15 |

795 |

- SMV series of vibrator motors are specially developed for variable individual application to suit all working environments.

- The vibrator motor develops centrifugal force from 5 kg (50 N) to as much as 6000 kg (60000 N)..

- Higher and non standard rating vibro motors on request

Technical Specification

Bearings: Spherical Roller as optional upto 2 HP

Material: C.I. Grade 25, Spheriodical C.I & Steel ( Optional), SG Iron

Power Supply: Vibrator motors are suitable for 220V – 1Ø, 415V -3Ø, and 50 / 60 Hz. Power supply

Operations S1, S4, S7

Mechanical Protection: IP 44, IP 55, IP 67 (on request)

Electrical motor: Energy Efficient motor with vaccum Impregnated stators. An extra moisture proof coating is provided on the status for improving the mechanical strength .

Insulation Class: Class F ( 155°C ), Class H ( 180°C ), Class H(on request) can also be supplied.

Drive Shaft: This is made of treated steel alloy able to withstand high stress

Eccentric Weights: Each vibrator is supplied with one or two weights on each side as per the requirement of centrifugal force.

Casing & Bearings

Casings made of high graded CI (Grade 25) and cast steel castings are also available. The bearings are exclusively supplied by SKF for vibro motor applications.

Thermal protection

Thermistor of class F (155°C) available on request.

Brake Motors

Factory fitted Motors with EMCO Dyna Torque DC brake 14.458 and AC brake, AC 1000, other brand of brakes on request

Brake Motors are available with the braking torque of 4NM to 800 NM (Size 6 – Size 40)

Features

- Low rotor Inertia

- Manual Release

- Adjustable Brake Torque

- Simple Wear Adjustment

- Low Power Requirement

- Residual Free

- Fast Switching Times

- Simple Construction

Bench Grinders

Features

- Compact and mechanically robust

- Conforms to IS 2538- 1963

- Economical in power consumption

Constructional Features

- 8″ Bench grinder is of Cast Iron construction

- Deep grooved bare bearings for ample load baring capacity

- Wheel Specification

>> A 36-Q 5-V 99 Coarse

>> A 60-P 5-V 99 Fine for 152 mm – 178 mm and 203 mm

>> A 45-Q 5-V 99 Coarse

>> A 60 -P 5-V 99 Fine for 250 mm 1420 RPM Machine

>> A 24-S 4-B 14 Coarse

>> A 46-R 5-B 14 Fine for 250 mm 2800 RPM Machine

Wheel Guards

Heavy C.I. Wheel Guards

- Designed to afford full protection to the worker with maximum freedom of operation

- Fitted with adjustable spark deflectors to provide maximum safety to the operator

- Fitted with easily-detachable covers for quick replacement of wheels.

Tool Rests

- Adjustable tool rests ensure maximum grinding; fitted with a single mounting-screw that locks them rigidly in place, yet may be quickly removed for accessory attachmen3ts

- They adjust completely for the exact grinding angle desired. Note the special wrap – around ledges that permit grinding from both sides as well as the face of the wheel

Motors

- Totally enclosed, naturally cooled

- Suitable for intermittent duty, slim design of motor with the extra-long and bells assures ample clearance for grinding odd-shaped items and long stock

- Windings insulated with Class ‘F’ materials and varnished to suit tropical conditions

- Three phase motors suitable for 400-440 V, 50 CY A.C. supply. Performance conforms to IS 996. They are of the permanent split phase capacitor type

- Rotors, dynamically balanced, assure extra-smooth operation

Switch

- Rotary Switch on 3 Phase and Single Phase Machines

Lubrication

- Ball Bearing grease, preferably MP – 3 – Burmah – Shell

Bench Polishers

- HP : 0.33 to 1 HP

- Speed : 3000 RPM Syn

- Phase : Single OR 3 Phase

Three Phase Motor

|

Foot Mounted Motor |

Flange Mounted Motor |

Face Mounted Motor |

2 Pole& 4 Motors |

6 Pole& 8 Motors |

Mechanical Features |

Non standard motors |

Features

- Speed: 750 / 1000/ 1500/ 3000 rpm

- Volt: 42v/48v/110v/220v/380v/440v/670v

- Special motors to use with invertors

- Fitted with SKF Bearings

- Duty cycle S1, S2, S3, S4 & S7

Application

- Compressors, Blowers, Fans

- Vacuum pumps, Air curtains

- Printing Machinery

- Knitting Machines

- Drilling Machines

- Buffing & Polishing Machines

- Mosaic floor polishing machines

- Grinders

Standards

| IS:325 | Three phase Induction motors-specification. |

| IS:900 | Code of practice for installation and maintenance of Induction motors. |

| IS:1231 | Dimensions of Foot mounted A.C. Induction motors. |

| IS:2223 | Dimensions of Flange mounted A.C. Induction motors. |

| IS:4029 | Guide for testing Three phase Induction motors. |

| IS:4691 | Degree of protection provided by Enclosures for Rotating Electrical Machinery. |

| IS:6362 | Designation of Methods of Cooling for Rotating Electrical Machines. |

| IS:12065 | Permissible limits of noise level for Rotating Electrical machines. |

| IS:12075 | Mechanical Vibration of Rotating Electrical machines |

| IS:12615 | Energy Efficient Induction Motors Three phase Squirrel Cage. |

International Standards

| IEC 60034-1, 5 | Rotating Electrical Machines – Rating and Performance, Degrees of Protection |

| IEC 60072 | Dimension and output ratings of Rotating Electrical machines. |

- Insulation – Class F

- Supply – 415v, 50Hz

- Standard cooling – Totally enclosed fan cooled

- TENV on request

- External forced cooling on request

- Enclosure – (IP 54 or IP 55 on request)

Stator Frames and End Shields

- These are rugged components of cast iron confirming to IS 210

- The stator frames are of deep fin construction to ensure adequate cooling surface

Terminal Box

- Terminal box is located on the right hand side of the motor when viewed from ‘D’ end

- The terminal box is turnable at 90o to permit cable entry from any direction

- Multi mount option is available on request

Rotor and Shaft Assembly

- Pressure die-cast aluminium rotors

- Dynamically balanced for vibration free operation

Stators

- All copper windings, copper wires confirm to IS 4800 – Part V

- Surge tested for short grounds and phase unbalance

- Multiple dips protect against heat, moisture and contaminants

- Wound Stators are Vacuum Impregnated with high temperature insulating varnish. A final dip in red epoxy insulating enamel provides a protective over coat

- 80 Frames is available with multimount option

Insulation

- class F

- Non-hygroscopic, high dielectric and mechanical strength

- Epoxy coating provides additional protection

- Class H on request

Bearing

- Cast iron housing

- Double side shielded bearing upto 100 frame

- Pre-packed lubricants from SKF BEARING

Testing

- All motors are tested in the course of manufacture and before dispatch as per relevant Bureau of Indian Standards (IS 325) and EN60034-1

Ranges

- Range : 0.18 KW (0.25 HP) to 22 KW (30 HP)

- Speed : 350/500/750/1000/1500/3000 rpm

Standard Motors

|

K.W |

H.P |

2 Pole |

4 Pole |

6 Pole |

8 Pole |

|

0.09 |

0.125 |

56 |

56 |

71 |

71 |

|

0.12 |

0.16 |

56 |

63 |

71 |

71 |

|

0.18 |

0.25 |

63 |

63 |

71 |

80 |

|

0.25 |

0.33 |

63 |

71 |

71 |

80 |

|

0.37 |

0.5 |

71 |

71 |

80 |

90S |

|

0.55 |

0.75 |

71 |

80 |

80 |

90L |

|

0.75 |

1.0 |

80 |

80 |

90S |

100L |

|

1.1 |

1.5 |

80 |

90S |

90L |

100L |

|

1.5 |

2.0 |

90S |

90L |

100L |

112M |

|

K.W |

H.P |

2 Pole |

4 Pole |

6 Pole |

8 Pole |

|

2.2 |

3.0 |

90L |

100L |

112M |

132S |

|

3.7 |

5.0 |

100L |

112M |

132S |

160M |

|

5.5 |

7.5 |

132S |

132S |

132M |

160M |

|

7.5 |

10.0 |

132S |

132M |

160M |

160L |

|

9.3 |

12.5 |

132M |

160M |

160L |

180M |

|

11.0 |

15.0 |

160M |

160M |

160L |

180L |

|

15.0 |

20.0 |

160M |

160L |

180L |

200L |

|

18.5 |

25.0 |

160L |

180M |

200L |

225S |